We are keeping pace with the food industry with new designs and manufacture a new level of flexible material handling equipments capable of easy clean and safety so that help food plant business can be quickly adapt to more and more higher requirements in the market. We create our flexible material handling solutions with great capability to handle a large variety food or non-food industry in different shapes, such as liquid or semi-liquid, powder, small or big / regular or irregular solid granules. Easy clean, easy release and easy maintenance is our main starting point. We have very good experience in stainless steel processing with higher quality in laser-cutting, turning, drilling, grinding, whole-welding, bending or forming, and we also use water-jet technolgy in steel plate cutting in order to ensure all the steel parts to be protected precisely without defects. Meanwhile, we have special handling technology for corrosion material project. All the belts on the conveyor we're using is blue blue color and food grade version according to European and American market standard, food grade PP bucket, modular link-belt, flat belt and skirt-belt is available.

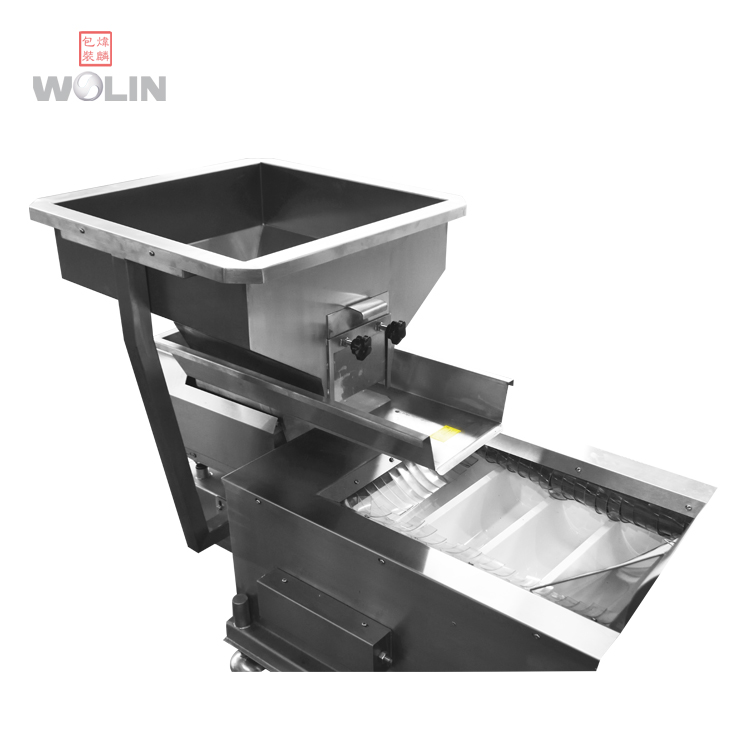

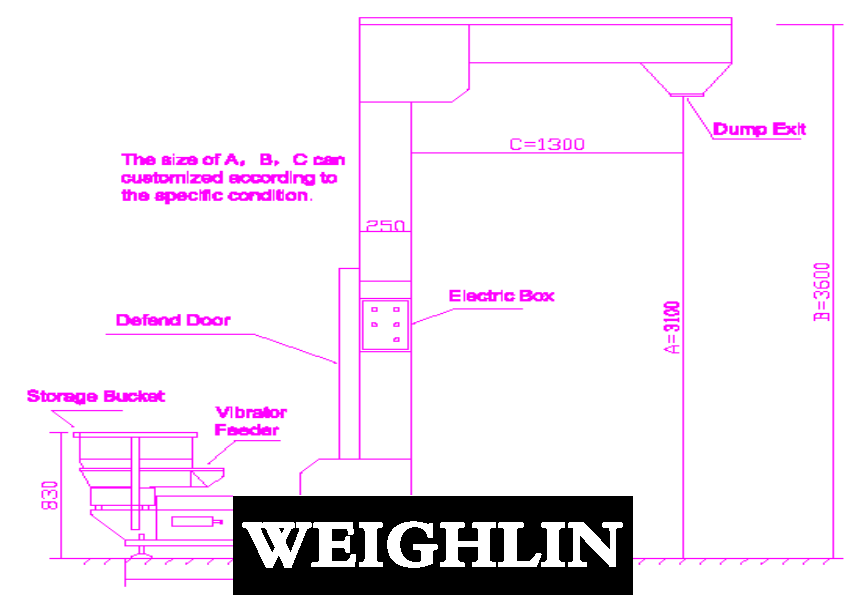

New modular Z type bucket elevator with modular parts design and build is for conveying vertically the bulk granule material to the weighing or packaging system.

APPLICATION

• Pet food • Snacks • Confectionery

• Rice • Seed • Dry Fruits

Working Process

The bulk material is put inside the infeed hopper, through vibrator vibration, the material was dropped into the bucket, and the belt will be moved by motor inclinely forward to the top funnel of weight filler or packaging machine.

Options:

1L bucket

4L bucket

Big Loading Hopper

sales@weighlin.com

sales@weighlin.com