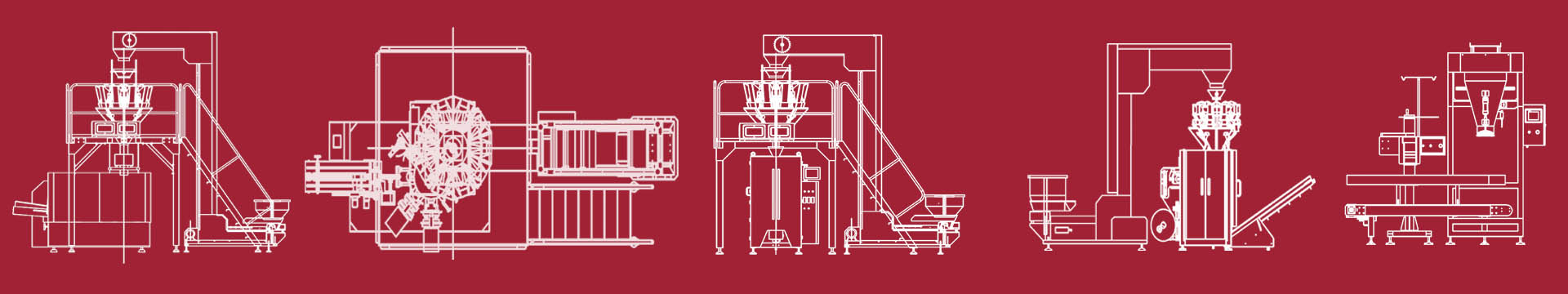

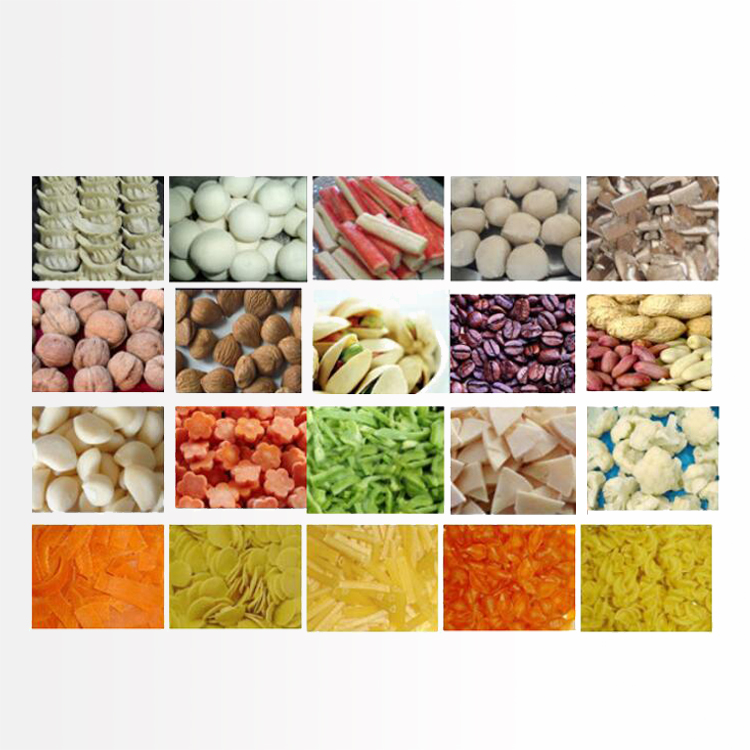

Packing carry, deliver and create value. With its advantage of performed pouches

good quality, elegant image with unique zip-lock standup style design, it is good to

enhance company impression, which is becoming more and more popular with the

food plant. Combined with years industry experience, Welin has worked out several

models of single station mini doypack machine and 6-8 station rotary pouch packing

machine with the function of pouch pick-up, open, fill and seal, also options available:

date printer, MAP function, auto zipper opener or output conveyor, etc. Compact

design, safety and hygiece, easy clean, easy operatioin and easy maintance, various

bag size and style run on the same machine; High quality components ensure long

time reliable performance, no pouch, no materail, no running, popular in Europe &

America market. Most used for SME plants, small footprint, limited invest, flexiable

application, apply for liquid, powder and granules, workable for 3-side seal, zip-lock

doypack pouch, gussette, Kraft open-window performed pouches, etc.

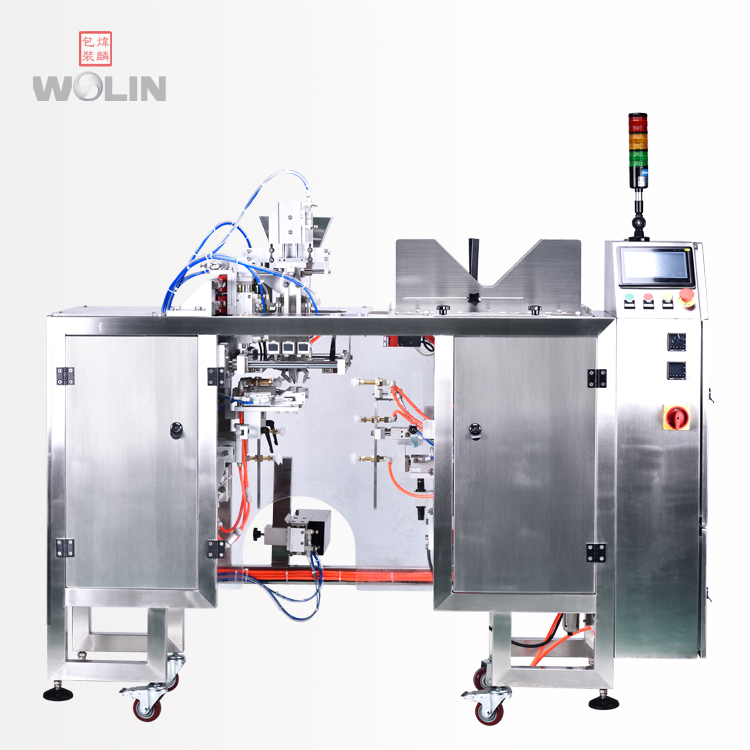

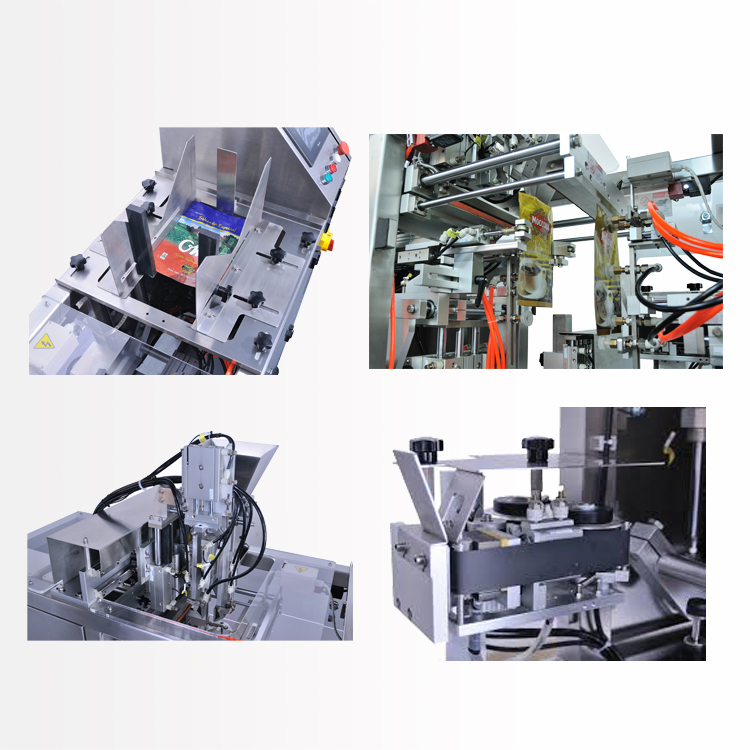

New Generation Sanitary Design & Build

New version frame design for easy clean and avoid trash accumulated.

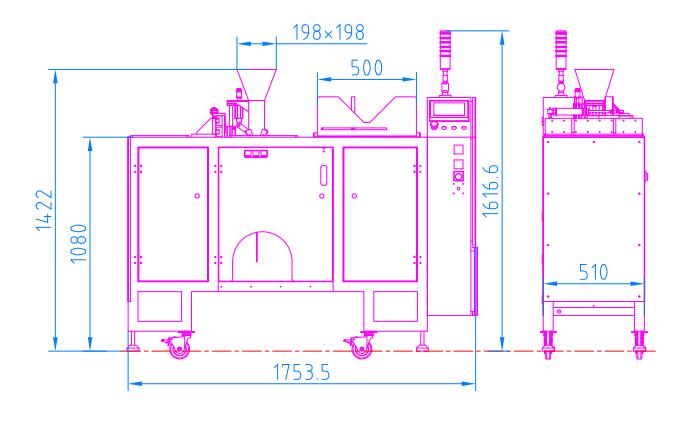

Compact footprint & Low Maintenance

Compact single station footprint, pneumatic system used for safety running & low maitenance.

Auto Operation Control Multiple Function

From pouch suck up - open - fill - seal to output which is controlled by PLC and user's friendly H.M.I. ensure high efficiency performance.

Easy to Adjust Bag Types and Sizes

Depending on product condition and pouch type, main menu settings can be set on the screen, multiple pouch type can run on the same machine by suction position adjusting.

No Pouch, No Dump for Normal Running

Auto pouch detecting sensor, no pouch no dump ensure material splash down.

Auto Trouble-shooting

Automatic breakdown detection and solution is displayed on the screen clearly.

Flexible Customers Made

Various option functions are available as per request, such as auto zip-lock open device/Hot Stamp Printer/ Hopper Shaker/ Product Settler.

Main Parts of Mini Doypack

PLC Control, Touch Screen, Temperature Control, Automatical Pneumatic Components, Gas Processor, Alarm.

Building Material of mini doypack

The frame is made of 304SUS, some parts is Aluminum alloy or painted.

Interlock Safety, CE Application

Auto stop when the door is open,

sales@weighlin.com

sales@weighlin.com